Euro 24: Keep The Game Flowing

In football, they say the game should flow. Ensuring that it does on the pitch requires a high-performance and sustainable water supply...

To meet the objectives of global climate protection and decarbonisation, wind and solar energy are under public scrutiny. But a clean and sustainable source of energy is often overlooked. In contrast to sun and wind, it offers a constant supply: geothermal energy. In this blog, you will learn about the opportunities offered by geothermal energy and why plastic pipe systems make it possible to use this inexhaustible energy resource economically.

The natural production of energy from the earth's interior is by no means a modern invention: since ancient times, people have been using geothermal springs for heating purposes and as natural thermal baths. However, it is only in recent decades that technological development has made it possible to develop geothermal energy on a large scale for power generation and as a sustainable source of heat.

Geothermal energy is based on a simple principle: the earth generates enormous amounts of thermal energy in its core, which warms the mantle and crust. This natural heat is brought to the surface through pipelines and converted into usable energy. At the same time, the process of energy generation is almost CO2-free. However, the use of geothermal energy not only offers the opportunity to significantly reduce the CO2 footprint, but also to ensure a reliable and cost-efficient energy supply in the long term.

Geothermal energy is an all-rounder when it comes to renewable energies: it can produce base-load electricity and also offers the possibility of operating heating and cooling systems – in other words, an attractive triple function as a source of electricity as well as heating and cooling.

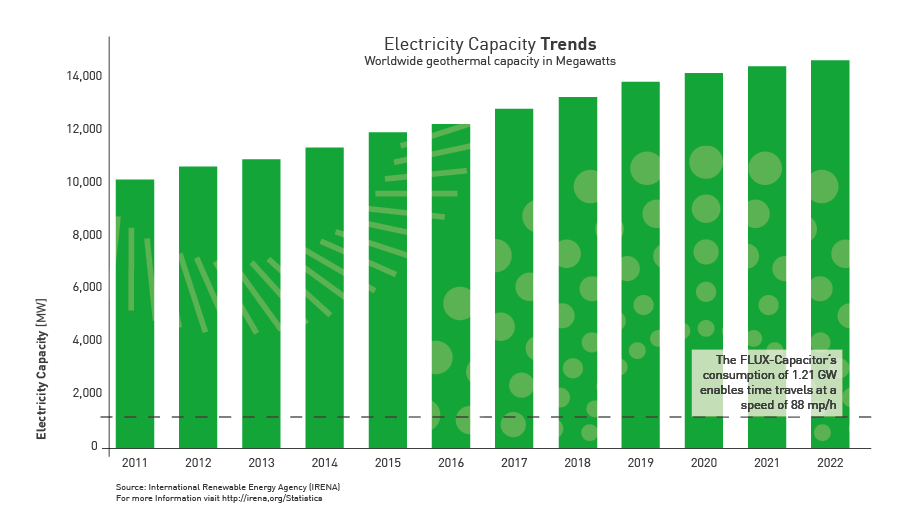

Despite its potential as a clean and reliable energy source, a look at the global energy situation shows that geothermal energy still plays a marginal role.

Investments in established technologies such as solar and wind accounted for 95% of the total in 2022. Other renewable energies, including geothermal energy, accounted for only 7% of investments.

Electricity generation from geothermal energy has grown globally at a moderate rate of about 3.5% annually, reaching a total installation capacity of approximately 15.96 gigawatts of electricity (GWe) in 2021. This means that geothermal energy accounts for only a small share of 0.5% of renewable energies for electricity generation and heating and cooling.

Despite the low share, the trend shows that geothermal energy is growing. The use of geothermal energy for heating and cooling purposes grew by an average of about 9% annually between 2015 and 2020, resulting in a thermal capacity of 107 gigawatts (GWth) in 2020.

Geothermal energy offers enormous growth potential for the global energy industry. Countries with favourable geological conditions show that a comprehensive use of geothermal resources is possible.

Countries with volcanic activity or tectonic faults particularly benefit from geothermal energy, as it facilitates geological conditions and therefore access to geothermal resources. Examples of such include:

Iceland: Thanks to its volcanic activity, Iceland uses geothermal energy for heating, electricity generation.

Philippines and Indonesia: Both countries are among the leaders in geothermal power generation, aided by their location in the Pacific Ring of Fire.

New Zealand: This country uses its geothermal resources for power generation and industrial applications.

Kenya: It is one of the leading countries in Africa that uses geothermal energy to generate electricity, especially in the Rift Valley.

United States: Especially in California, Nevada and Hawaii, geothermal energy is used for electricity and heating.

The temperature of the Earth's interior rises with increasing depth. This phenomenon is called the geothermal gradient. This gradient can vary depending on geological conditions. It averages around 25°C to 30°C per kilometre in the earth's crust. In volcanically or tectonically active areas, the temperature increase per kilometre depth can be significantly higher. A distinction is made between different forms of geothermal energy, depending on the depth. Each has its own significance and applications for energy production. The different types of geothermal energy offer solutions for a wide range: from the provision of district heating to the decentralised supply of heat through geothermal heat pumps to large-scale electricity production.

At these depths, the temperature can exceed 60°C; temperatures of over 100°C are often reached at a depth of a few thousand metres. Deep geothermal energy mainly uses the high temperatures to generate electricity generated by turbines or generators. This type of geothermal energy is particularly present in volcanic areas, where hot rock layers are easily accessible. Power plants using this form of energy can provide a large amount of baseload electricity, which forms the backbone of any energy supply network.

Medium-deep geothermal energy uses geothermal energy in a temperature range of about 25 °C to 60°C. It offers an efficient solution for the heat supply of buildings, greenhouses and industrial processes. By taking advantage of the relatively stable temperatures at this depth, medium-deep geothermal systems can provide a constant source of energy, ideal for heating and, in some cases, cooling.

At this depth, temperatures can be between about 10°C and 25°C, which is ideal for running heat pumps. With this form of geothermal energy, the constant, moderate temperatures of the earth are used to heat or cool buildings. Near-surface geothermal energy is particularly suitable for heat pump systems used for air conditioning in private households and industry.

When it comes to selecting the right piping material for geothermal applications, there is virtually no alternative to plastic pipes. The reason for this is that their outstanding resistance to corrosion, flexibility and long service life set them apart from other materials such as steel and copper.

Plastic pipes are therefore essential for the use of geothermal energy. Steel pipes are susceptible to corrosion from chemical substances in the soil or water. The disadvantage for copper pipes, on the other hand, is the enormously high investment costs as well as the tendency to incrustation and therefore a high maintenance effort.

Piping systems made of polypropylene (PP) and polyethylene (PE) are particularly suitable for geothermal applications. Both plastics not only have high resistance to corrosive substances, but are also known for their flexibility, which makes them ideal for installation. In addition, their thermal properties ensure minimal heat loss, increasing the efficiency of the entire geothermal system. However, there are significant differences between the two materials: polypropylene PP has higher rigidity, hardness and strength than polyethylene PE. The upper service temperature is 95°C and PP can withstand temperatures of up to 150°C for short periods. For polyethylene, the limit is 60°C. Therefore, depending on the application or project, the right pipe material is crucial.

The installation of plastic pipe systems is easier and faster than that of metal pipes. Modern joining techniques, such as plastic welding, create durable, tight joints that guarantee safe long-term use. These installation benefits lead to accelerated project implementation and therefore a reduction in labour costs.

The environmental compatibility of plastic pipes also plays an important role. They are energy-efficient to manufacture and often recyclable at the end of their life, which significantly minimises the ecological footprint compared to metallic systems.

The range of possible applications of geothermal energy is impressive. But it also delivers what it promises in practice. Two examples of projects in which aquatherm pipe systems were used demonstrate the cost-effectiveness and sustainability for the energy future.

The project of Stadtwerke Arnsberg is a milestone in municipal energy supply. With the planning, which began in June 2005, Arnsberg wanted to become a pioneer in the use of renewable energy sources. At the time of planning, it was Germany's deepest borehole. The goal: to heat the "Nass" leisure pool with 2.1 million kilowatt hours per year with maximum energy yield.

The challenge lay in the depth: with a temperature increase of about 3°K per 100 metres, an impressive 83°C was measured at the bottom of the 2835-metre-deep borehole. This heated water should be brought to the surface with almost no loss in order to use the heat and then return the cooled water to the depths.

But there were problems: the GRP double-walled pipes (glass fibre reinforced plastic) intended for the project proved to be unsuitable for withstanding the enormous loads. As a result, a worldwide search for a robust and innovative solution began. aquatherm, which became aware of the Arnsberg problem through numerous media reports, proactively contacted the municipality and the drilling company. Thanks to aquatherm's experience, it was possible to develop a suitable solution.

After in depth tests at the Institute of Petroleum and Natural Gas Technology at Clausthal University of Applied Sciences, in which the composite pipe from aquatherm passed various tests, it was presented to the Arnsberg city administration. The innovative pipe system consists of an outer steel pipe with an inner lining made of the PP plastic pipe aquatherm green. Even under extreme conditions, such as those prevailing at the base of the deep borehole, the pipe system proved its reliability – it withstood temperatures of 95°C and pressures of 320 bar.

The installation proceeded without any technical difficulties to the depth of 2,800 metres. Under the supervision of the Mining Authority and after the installation of the circulation pump on February 8, 2012, the project team quickly reached the target of 55°C hot water, reaching the earth's surface. The "Nass" leisure pool now benefits from the geothermally heated water. This project is a successful example of an accomplished energy transition: the local climate impact is reduced by about 800 tons of CO2 per year.

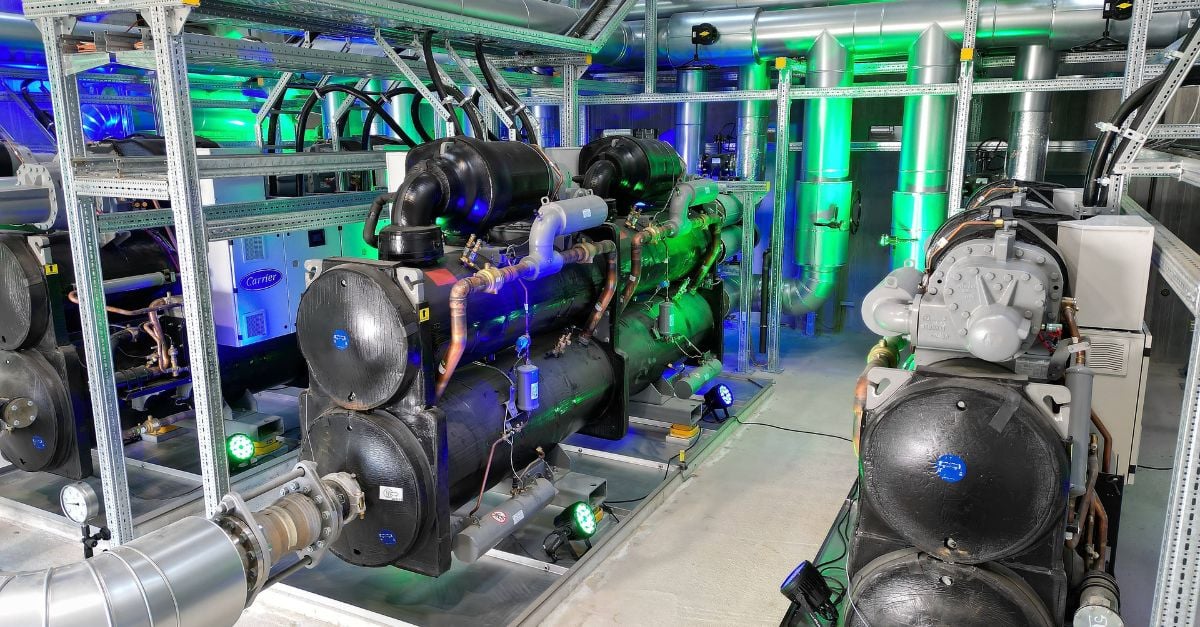

In 2023, Stadtwerke Schwerin's geothermal heating plant went into operation, setting new standards in Germany's sustainable energy supply. This future-oriented project in Schwerin represents an innovative approach to overcome the challenges of high mineralisation in thermal water.

The special conditions in Schwerin – thermal water with a high mineral content that is permanently under overpressure at around 50/70°C – required a piping system that could cope with these extreme requirements. The answer was found in aquatherm blue, which is robust enough to withstand the high corrosive influences.

aquatherm blue not only meets the technical requirements, but is also ecologically forward-looking. The geothermal plant of Stadtwerke Schwerin can generate around 15 percent of the district heating in Schwerin in a climate-friendly way with medium-deep geothermal energy and modern heat pump technology. For this purpose, the thermal water is first transported to the surface in order to use the geothermal energy through heat exchangers and heat pumps. After the heat has been extracted, the cooled water is returned to the rock layer, creating a sustainable and closed loop. The welded connection of the pipes ensures high reliability of the system, as there are no weak points. This is a particular advantage, as the thermal water is classified as hazardous to water and therefore the highest requirements are placed on the safety of the installation.

"Thermal waters, such as those extracted in the North German basin, place special demands on the piping material," explains Dr.-Ing. Frank Kabus, Managing Director of Geothermie Neubrandenburg GmbH, the project's consulting and planning office. "Due to the high mineralisation of up to 300 g/l, the corrosion resistance of the material is of course an essential aspect. In addition, for geochemical reasons, a permanent overpressure of a few bar must be maintained in the pipe system – at temperatures in the range of 50/70°C. aquatherm blue, made of polypropylene plastic, is an ideal solution under the conditions encountered. Oxygen ingress to thermal water, usually a disadvantage of plastic compared to metallic pipes, can be prevented in this case by integrating a diffusion barrier. This is essential, as otherwise it can lead to the formation of particles in the thermal water, which creates injection problems in the subsoil over time." Read more.

The aquatherm blue piping system offers a wide range of advantages that make it the ideal choice for demanding geothermal projects:

The aquatherm green PP pipe system is also ideally suited for geothermal applications – especially for deep geothermal energy:

With aquatherm blue or aquatherm green, the heat can be extracted from the earth, and with aquatherm energy it is transported to the consumers in a highly efficient manner. This is because the thermally insulated pipe system is suitable for modern district heating networks. The insulation properties of aquatherm energy minimise heat loss in district heating networks and are therefore ideal for the requirements of 4th generation district heating. This provides customers with a holistic solution from a single source.

aquatherm offers much more than just high-quality pipe systems. Customers benefit from comprehensive support and services that ensure safety and efficiency at various levels.

From the very beginning, aquatherm experts are at the customer's side to help with the technical planning and design of the systems.

aquatherm offers digital tools and services that particularly facilitate the planning process. These digital solutions include BIM support, planning software, and apps.

aquatherm's customer service provides answers to technical questions, conducts training for installers and planners, and provides support during commissioning.

With projects all over the world, aquatherm has a broad international experience, from which customers benefit in the implementation of their projects.

aquatherm's products are comprehensively certified and the sustainability of aquatherm blue, aquatherm green and aquatherm energy are documented in EPDs. This gives customers the assurance that they comply with national and international standards.

The extensive support and high-quality products offer a high level of project security.

Due to the long service life, minimal maintenance requirements and the efficiency of the piping systems, the initial investment pays for itself quickly and sustainably.

Thanks to the reliable planning and installation processes, aquatherm enables a high level of deadline reliability for projects.

The benefits of geothermal energy are clearly defined and its role in future energy supply is undeniable. Geothermal energy stands for a clean, reliable, CO2-free, renewable energy source. It has the ability to deliver a continuous base load, regardless of the weather:

Due to their special material properties, the aquatherm blue, aquatherm green and aquatherm energy pipe systems are crucial for the successful implementation and operation of geothermal plants as well as for transport in district heating networks.

You can find more information about our products on our website.

In football, they say the game should flow. Ensuring that it does on the pitch requires a high-performance and sustainable water supply...

At first glance, the combination of ice storage and a heat pump may seem contradictory. However, this synergy offers a highly efficient, economical,...

Data centres can be cooled using either air-cooled or waterless-cooled systems. Deciding which method is best suited for the future raises important...