Expanding district heating faster and more sustainably

The world is striving for the so-called "Net Zero Emissions by 2050" as a goal. This means that CO2 emissions are to be completely reduced to zero by...

Sprinkler systems play a central role as one of the most widely used and effective solutions in fire protection. In an emergency, they save lives and protect property. In the event of a fire, sprinkler systems not only provide an immediate response to contain the fire, but also help prevent the spread of flames and extend evacuation times.

The effectiveness of the sprinkler system relies on the type of sprinkler head and the quality of the piping. Only harmonious interaction results in a safe overall system. aquatherm red is a groundbreaking innovation in sprinkler piping systems. It is the first plastic sprinkler piping system to receive certification from VdS Schadenverhütung GmbH, Europe's leading institute for corporate safety. The fusiolen PP-R FS pipe material has been specially designed to meet the high demands of sprinkler systems and offers unsurpassed safety due to its flame-retardant properties and corrosion resistance.

The system is not only VdS certified, but also tested and approved in many countries around the world, which underlines its quality and reliability. Fusion technology is used to weld the pipe and fitting, which guarantees a permanently tight connection. Unlike metal piping, aquatherm red is corrosion-resistant and resistant to chemicals, which significantly extends the life of the system. The low weight and easy handling of the material allow for quick and cost-effective installation. The system is suitable for a wide range of applications, from industrial and commercial buildings to hotels and stadiums. In addition, it provides an excellent basis for the application of low-pressure fine spray technology. This technique requires less extinguishing water than traditional sprinkler systems, which significantly reduces the risk of water damage to the building fabric and interior design.

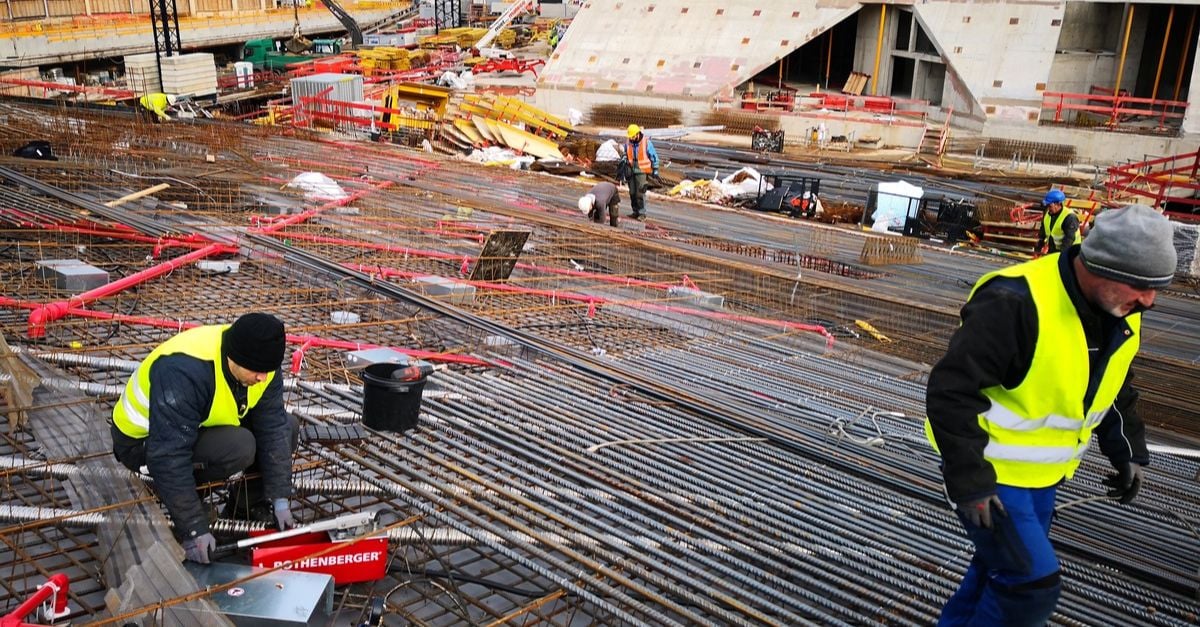

A special unique selling point of aquatherm red is that it can be laid directly in in-situ concrete or in precast concrete elements, e.g. filigree ceilings. Due to its flexibility, the aquatherm red system can also be easily integrated into the floor slabs in the case of wooden body ceilings in which air chambers are used to reduce the need for concrete.

Unlike metal systems, which are prone to corrosion in damp concrete and therefore require special protective measures, aquatherm red remains corrosion-free. This not only saves costs, but also simplifies the construction process. Builders benefit from lower shell construction costs and an efficient space-saving integration of fire protection into the building design.

The integration of aquatherm red into modern construction projects shows that effective fire protection and sophisticated architecture do not have to be mutually exclusive. The system offers an almost invisible fire protection solution by laying it in concrete, which opens up more architectural freedom. aquatherm red shows how technical safety requirements can be harmoniously integrated into the design concept without compromising aesthetics.

Given the global shortage of skilled workers, there’s a heightened demand for solutions that facilitate both time and cost savings. With prefabrication, aquatherm offers exactly the service that the industry needs. All the necessary string and supply lines of a sprinkler system can be prefabricated at aquatherm according to drawings and shorten the installation times on the construction site. Industrial prefabrication is worthwhile for planners and fabricators.

The new high-rise building on the UN campus in Bonn is not only an architectural highlight on the Rhine, but also a showcase project in terms of sustainability, energy efficiency and safety. With its 18 floors, it forms a central point for the United Nations in Bonn. For fire protection in this architecturally and ecologically progressive building, the aquatherm red piping system was chosen. The piping system was integrated directly into the concrete ceilings. Around 2,800 metres of pipes were used. The installation in the hollow-core ceilings allowed for maximum design freedom and an invisible integration of fire protection. The use of aquatherm red instead of metal sprinkler systems, which would require special protection measures against corrosion in concrete, simplified construction and contributed to cost savings. The efficient prefabrication of the strings in the aquatherm plant played a decisive role in the on-time completion of the building. The pre-produced elements reduced the time required for welds on the construction site and enabled more effective planning and optimised deployment of assembly personnel. In addition, the low weight of aquatherm red compared to steel pipelines made handling much easier and therefore supported a smooth construction process.

In Düsseldorf, the Kö-Bogen I and II projects were equipped with the aquatherm red sprinkler system in order to meet the highest safety and sustainability standards. With its striking glass and natural stone façade, the Kö-Bogen I has become a new landmark of Düsseldorf. With Europe's largest green façade and a green, walk-on roof, the adjacent Kö-Bogen II fits seamlessly into the sustainable architectural philosophy. For the fire protection of both Kö arches, aquatherm red was chosen, which was laid directly in the concrete. The elements individually prefabricated by aquatherm significantly minimised the amount of work on the construction site and facilitated on-time completion. More than 3,400 sprinkler connections and 6,500 metres of pipe were installed, with the leak test already carried out at the factory. In addition to its flame retardancy, the aquatherm red material fusiolen® PP-R FS ensures excellent corrosion resistance – a clear advantage over metallic systems that could corrode in damp concrete. Not only the easy-to-install properties of polypropylene are convincing, but also the ecological advantages: The material significantly reduces CO2 emissions during production compared to steel or other metal pipe systems; it offers a significantly longer service life and can be recycled in an environmentally friendly way without much energy expenditure.

The KTM Motohall in Mattighofen, Upper Austria, is a special museum that offers visitors insights into the world of KTM on over 2,600 square metres. The unusual metal structure, which mimics a tyre track, and the internal structure, which guides visitors along a replica racetrack, required a high degree of flexibility and adaptability of the technical equipment, especially in the field of fire protection. For the fire protection system, the aquatherm red system was chosen, which, thanks to its integration into the exposed concrete ceilings, blended invisibly into the architectural concept. This decision criterion was crucial to meet the aesthetic requirements of the building while ensuring the highest level of safety. Unlike traditional metallic sprinkler systems, which require special anti-corrosion measures when installed in concrete, aquatherm red offers an effective solution. Thanks to fusion, the approximately 2,200 metres of pipe were seamlessly welded together, creating a homogeneous, material-locked unit, ensuring safety. The pipe and fitting were briefly warmed up using specialised tools, allowing them to be easily joined together. The pipes supply a total of 725 sprinkler heads. The use of prefabricated tubular elements played a decisive role in meeting the ambitious schedule. In addition, the light weight made it much easier to transport and assemble.

The key to effective safety lies in the holistic integration of structural, technical and organisational fire protection. The comprehensive inclusion of these three pillars not only effectively prevents the occurrence and spread of fire, but also saves valuable time in the event of an emergency to save lives and preserve property.

The selection and implementation of the right sprinkler system such as the aquatherm red plays a central role in this. Compared to metal pipes, the plastic system offers significant advantages in terms of fire protection and corrosion resistance. The references show this impressively. They also make it clear that fire protection and aesthetic architecture are not opposites, but can complement each other.

Find out more about aquatherm red:

The world is striving for the so-called "Net Zero Emissions by 2050" as a goal. This means that CO2 emissions are to be completely reduced to zero by...

aquatherm pipe systems are easy to work with and are characterised by their corrosion and chemical resistance, durability and lower weight. How to...

How can the modern shipbuilding industry meet the increasing challenges of weight, corrosion, and environmental sustainability? Why are more and more...