In the fight against climate change, the construction industry is being called upon - and it must react by developing environmentally friendly, sustainable solutions. After all, the influence of the construction industry on global energy consumption is greater than one might assume at first glance.

The European Union's goal is climate neutrality by 2050. But in order to achieve the goals of the Paris Climate Agreement, the construction industry must rapidly reduce its energy consumption. A report by the European Academies Science Advisory Council (EASAC) makes this clear. This report attributes 25% of Europe's greenhouse gas emissions to energy consumption in buildings alone. The construction industry is therefore faced with the task of developing far-reaching and rapid measures - both in the operation of completed buildings, in new builds, and renovations.

In the following article, we‘ll show you why the construction industry has such a high influence on global energy consumption and the solutions which have been developed so far.

The construction sector is responsible for 36% of global energy consumption

Climate change is one of the greatest challenges of our time. The main problem is emissions - that is, CO2 released en masse. This enters the atmosphere and intensifies the greenhouse effect. The result: the earth continues to heat up.

According to the Global Alliance for Buildings and Construction (GlobalABC), the construction industry is responsible for 36% of global energy consumption and 37% of energy and process-related CO2 emissions (as of 2021). A considerable share for a trade. But it can also represent an opportunity as the figures make it clear that the construction industry has great potential in terms of climate and environmental protection. However, this only applies as long as innovative solutions are found that reduce energy consumption.

What is being done to reduce energy consumption in the construction industry?

There are already a number of programmes that address the question of how the construction industry can become more ecological. We present three approaches to you:

GlobalABC Roadmap for Buildings and Constructions

The UN's environmental protection programme, the Global Alliance for Buildings and Construction (GlobalABC) promotes a zero-emission, efficient and resilient buildings and construction sector. To meet the goals of the Paris Climate Agreement, the GlobalABC provides incentives to the building sector, making sustainable construction more attractive. This is based on a policy framework that promotes cost-effective solutions and green innovation in both the public and private sectors. Specifically, the retrofitting of buildings and the construction of sustainable new buildings are supported. The aim is to mobilise all actors along the value chain: from planning to construction and operation to demolition.

In its Roadmap for Buildings and Constructions, the various actors are shown ways to decarbonise the building sector by 2050. As a framework - developed together with the International Energy Agency (IEA) - the Roadmap represents a comprehensive approach to reducing emissions in the building sector and does so across the entire life cycle of a building.

Life cycle analyses and environmental product declarations

The life cycle of a building includes the phases of strategy, initiation, planning, execution, use, and deconstruction. Historically, the building industry focused primarily on the aesthetic, technical and economic aspects of buildings. But now, energy-efficient concepts are being developed against the backdrop of climate change. These ensure the environmental compatibility of buildings by taking into account aspects such as energy consumption, emission levels and the sustainability of materials. In order to include all these points in the planning, the entire life cycle of a building and its building materials must be analysed.

This ensures all building materials are considered from the extraction of raw materials, through processing and use, to their longevity, disposal, or the possibility of recycling. The end result is a life cycle assessment that provides meaningful and communicable environmental indicators for the planning and construction of buildings. The life cycle assessments can also be used to provide building materials, building products, or building components with environmental product declarations (EPD). These show the impact of a product on the environment and allow comparison to different products.

DGNB Guideline on the Use of Life Cycle Assessment

Planners and architects can use life cycle assessments as a planning and optimisation tool to design ecologically oriented buildings: on the one hand, to select sustainable building materials and, on the other, to optimise the building‘s energy consumption. The guidelines of the German Sustainable Building Council (DGNB) describe how life cycle assessments can be integrated into the planning process. It shows the benefits of life cycle assessments in the construction industry, highlights their potential in the various service phases, and provides tools for calculating and visualising life cycle assessment results.

Green products: Building with recycled and sustainable building materials

The use of life cycle analyses and environmental product declarations identifies the building materials that belong to the group of green products that‘ll assist in the reduction of CO2 emissions within the construction industry. Using the example of plastic pipe systems made of polypropylene from aquatherm, we show you how you can already use climate-friendly materials in the construction of buildings today.

Environmentally friendly plastic pipe systems

Pipes primarily provide for the transport of drinking water, cooling or other liquid media. They enable district heating or water circuits and serve as protection for power lines and broadband cables. In short: within the construction industry, pipes are indispensable because they fulfil important key functions. Nevertheless, the central importance of the pipe industry results in a certain obligation towards the global sustainability goals.

The plastic pipe industry in particular is making its contribution to climate protection, as the Fachverband der Kunststoffrohr-Industrie (KRV) recently made clear in its magazine: "Plastic pipe systems are already particularly ecologically sustainable due to their material properties. Since plastic is highly resistant and is characterised by its corrosion resistance, pipes made of this material have a long service life.

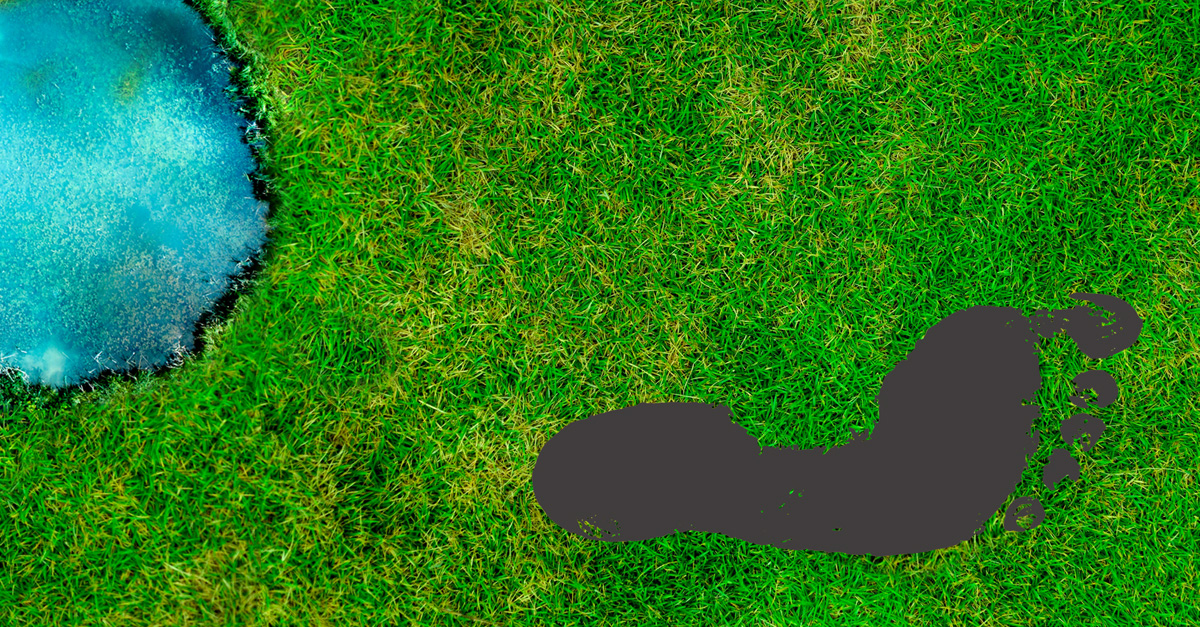

The environmental compatibility of plastic pipes is also made clear in a study by TEPPFA, the European Plastic Pipe Association, who analysed the effects of plastic pipe systems on the environment. The result: plastic pipe systems have an excellent environmental performance in various application areas and leave a smaller ecological footprint than pipe systems made of other materials.

For more than 50 years, one plastic that has been particularly suitable for plastic pipe systems has been polypropylene - a by-product of crude oil processing. Life cycle analyses in accordance with ISO 14040 examine its impact on the environment and studies show significantly lower CO2 emissions from pipes made of polypropylene compared to metallic raw materials such as steel or copper.

aquatherm is already committed to a sustainable construction industry

The company uses polypropylene to manufacture sustainable plastic pipe systems for the construction industry. aquatherm developed its first pipe system from polypropylene as early as 1981. In 1999, a further step was taken with the fibre composite pipe: this requires significantly less energy in the production process than the conventional aluminium composite pipe. Today, all company processes are geared towards the conservation of valuable resources, the minimisation of energy consumption, and the avoidance or recycling of waste.

aquatherm lives environmental protection in all areas of the company - and does so consistently. A look at the energy mix proves this: aquatherm obtains over 60% of its production energy from renewable energy sources. This is on average about 20% more than the average German mix. In addition, aquatherm intends to further supplement its energy mix with its own photovoltaic system in order to obtain even greener electricity. All these efforts have a positive impact on the company's environmental balance. aquatherm's environmental impact in terms of emissions produced is over 20% less kilograms per kilowatt hour in a national comparison.

aquatherm green: Plastic pipe with high environmental compatibility

The use of "green" aquatherm products improves the environmental balance of a building. The aquatherm green product family is characterised by a high environmental compatibility and leaves a significantly smaller ecological footprint compared to metallic pipe systems.

This innovative all-rounder is made of corrosion-resistant polypropylene. Due to its excellent ecological properties, it plays out its advantages particularly well in the field of drinking water applications, as it‘s completely free of heavy metals and toxic chemicals.

In addition to these ecological aspects, the plastic pipe also offers a considerable advantage for operation: thanks to its surface properties, the pressure loss with aquatherm green is low. Pumps require less energy for a permanently constant performance than in the interaction with metallic pipes and this is considerably more energy-efficient.

You want to know more about aquatherm green? You can find more details on the product page.

The construction industry must reduce its energy consumption

As one of the world's largest consumers of energy, it is important that the construction industry reduces its share of emissions by focusing more on sustainable solutions in the construction of buildings. The construction industry is already doing its part to protect the climate. However, it is a fact that the ambitions in the construction industry need to be promoted even further.

Sustainable innovations must be found, especially with regard to building materials. With its environmentally friendly and recyclable plastic pipe systems made of polypropylene, aquatherm is showing the way forward in the pipe industry. The use of green aquatherm products improves the environmental balance in many application areas. For example, in sustainable local and district heating projects ivia underground installation, through the pre-insulated aquatherm energy system. Or through aquatherm black, the surface heating and cooling system, which air-conditions buildings in an extremely energy-efficient way.

Do you want to know more about our projects? On our reference pages you will get an overview of the current projects of aquatherm piping systems.

Would you like to learn more about how aquatherm lives sustainability? Or do you want to know how you can achieve your goals in this area with our piping systems? Then we recommend you to take a look at our sustainability page.