What to look out for when converting to engineered polymer piping systems

Perhaps you are thinking about using engineered polymer piping systems instead of metal piping systems in your next project?

Due to its technical and ecological properties, polypropylene is a popular material for piping systems. Polypropylene pipes also impress with their good and simple processing during installation on the construction site.

Safe and stable connections are achieved by various welding methods. Such methods create stable and secure connections between individual PP pipes and their fittings: Leaks and the escape of liquids are avoided.

In this article, we will introduce you to various welding methods and explain what else you should look out for.

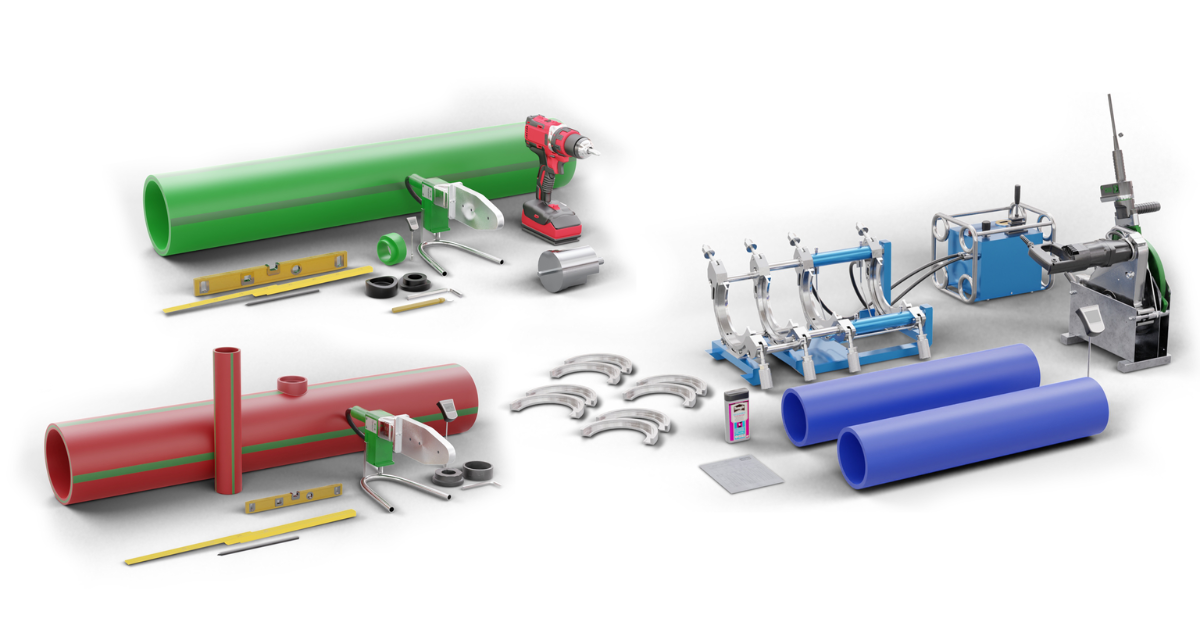

There are different welding methods for processing plastic pipes made of polypropylene. The diameter of a pipe determines which method of welding to choose.

In the following, we present some welding methods:

If you want to learn about welding methods in detail, take a look at our YouTube channel. Furthermore, you will find more information around the processing methods of aquatherm green, aquatherm blue, and aquatherm red on the respective overview pages.

Before starting the welding process you should familiarise yourself with and consider the following aspects:

When welding plastics, it is important to observe the following guidelines issued by the German Welding and Allied Processes Association (DSVDVS):

Temperatures and ambient conditions are critical to plastic welding. Therefore, be sure to protect your work environment from adverse weather conditions.

If you want to weld outdoors, you should bear in mind that you need an environment in which you can carry out all the necessary steps without compromising quality - regardless of the outside temperatures. In this regard, observe the specifications of the plastic pipe manufacturer. In addition, the parts to be joined must have the same temperature level and test welds guarantee that the welding process is exactly as desired.

With regard to the condition of the pipe, make sure that frost, ice, and moisture are removed during welding preparations. You should also keep molded parts free of frost and moisture.

The cleanliness of tools, surfaces and the environment is very important: the tools you use for welding must be free of contamination and checked for cleanliness before assembly.

If necessary, clean contaminants thoroughly with a non-fibrous paper. Also make sure that the surfaces to be welded are clean and dry. Contamination, dust, and moisture can have a negative effect on the final result. The same applies to the environment in which you are working: This should be clean and dry.

Do you know all the DVS guidelines? What ambient temperatures and conditions are ideal for welding? Are tools and surfaces clean? If so, then nothing stands in the way of processing your PP pipes.

On our product pages you can get an overview of the respective welding methods. If you prefer practical experience, we recommend attending one of our seminars in which we will familiarise you with the aquatherm products and their properties.

Perhaps you are thinking about using engineered polymer piping systems instead of metal piping systems in your next project?

The aquatherm green polypropylene product family is a pioneering solution for drinking water and supply pipes, as well as for maritime applications....

How can the modern shipbuilding industry meet the increasing challenges of weight, corrosion, and environmental sustainability? Why are more and more...